![]()

![]()

![]()

Construction

- precision angular contact bearings standard

- through hardened tool steel spindles

- case hardened steel bodies

- low friction rubber lip seals

- assembled with syntheric high pressure lubricant

- point angles ground in bearings, after assembly, for reliable accuracy

- sixty degree, fifteen minute nose angle standard on all J&S centers unless otherwise specified

- many standard cofigurations available to suit your special needs

- custom configurations also available

Capacities

- available in a broad range of sizes and capacities

- engineered to handle a wide variety of workpiece configurations with weights ranging from half an ounce to as much as two hundred ton

- tapers from number 1 Morse to number 48 Jarno are available

- rated for two thousand hours @ 100 rpm unless otherwise specified

(if centers are used below max capacity center life can be greatly extended)- workpiece expansion compensation is available

Selecting the Right Center

- Lathe Operation: Morse Tapers

- Grinding Operation: All Tapers

- Choose the point style your application needs. (Don't see what you need? Give us a call for a quote on your special dimension nose.)

- What is your workpiece weight? Choose a center with greater capacity to hold your workpiece to expect the full life of the center. (More capacity equals greater life expectancy.)

Engineering Information

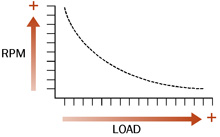

J&S Live Centers are designed to operate for 2000 hours at 100 rpm under maximum load conditions. Lighter workpieces will extend operating life whereas higher speeds or high thrust will decrease operating life. All J&S Centers have been designed to withstand a thrust loading of 35-50% of maximum workpiece weight.

The graph at left shows typical

speed vs. load characteristics

and life expectancy of J&S centers.

home | about

centers | live centers | dead

centers

wheel dressers | contact

us

All information

© 2001 J&S Tool Newton, New Jersey.

For more information contact J&S Tool at info@jstool.com